Accessories

- The Axvac Crane

- Cables & More

- Nozzles

The Axvac Crane

This movable hanging system for the vac tac spray guns – reduces operator fatigue, and at the same time allows completely mobility – so that every part of the mold can be accessed.

The boom is 3,5 meters long And can reach the furthest part of any mold. The spring of the tool-suspension system takes the weight of the gun, so the operator can guide it around the mold – without stain on the muscles. For further information – please contact AXVAC

Power Air and cables

Extension cable

Optional extension leads for TEC 6300 & TEC 7300 spray tools. Electro-pneumatic cordset allows operators greater reach & flexibility when working on larger composite applications. The extension leads is made in heavy duty materials – to ensure long life and minimize the risk of rupture of the cable. The standard length is 6 & 12 meters, Can be manufactured in desired length upon request

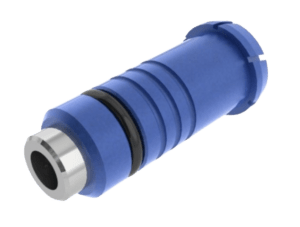

Power & air connector

The extension leads is provided with a throttle valve in the end – near the connector. This valve is for adjusting the spray for achieve an ideal spray pattern.

The LED Power & Air cord

Optional extension leads for TEC 6300 & TEC 7300 spray tools. Electro-pneumatic cordset allows operators greater reach & flexibility when working on larger composite applications. The extension leads is made in heavy duty materials – to ensure long life and minimize the risk of rupture of the cable. The standard length is 6 & 12 meters, Can be manufactured in desired length upon request

Supportstand for VacTac gun

The supportstand prevents the gun from falling over while in use, this is crucial for the glue not to run back through the VacTac system

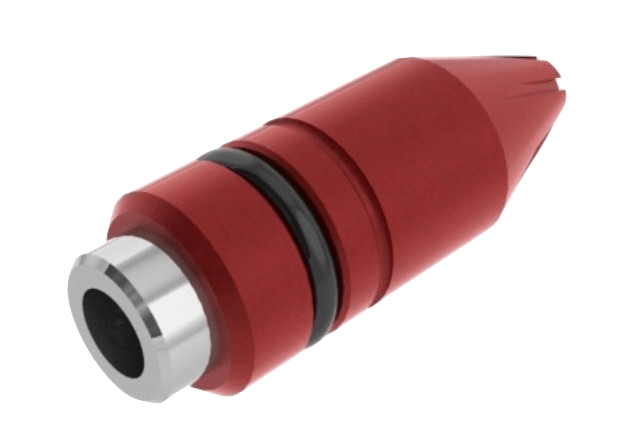

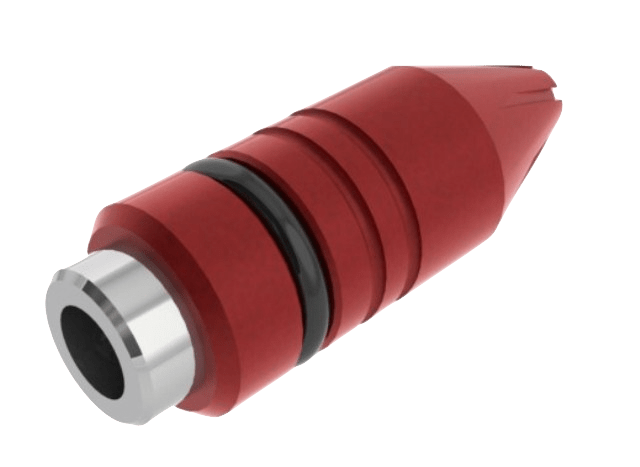

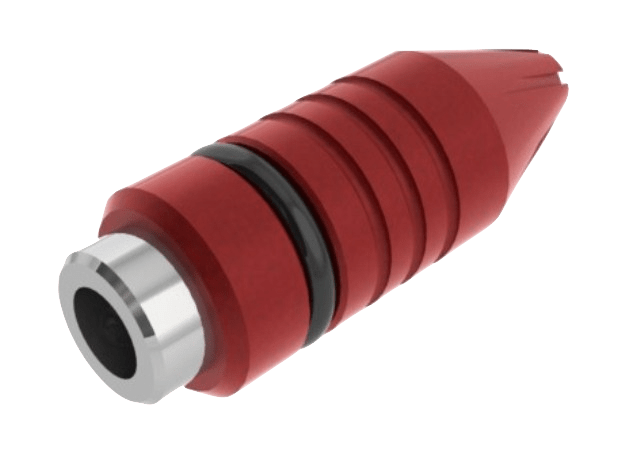

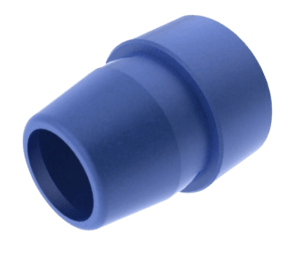

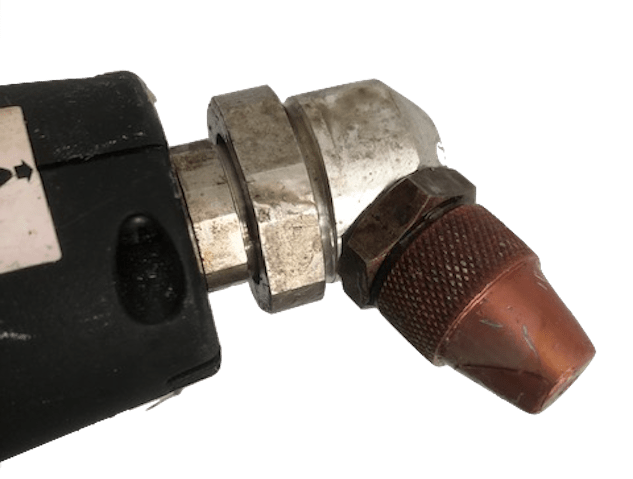

Nozzles